Physically cross linked polyethylene foam is a versatile material that has found its way into various industries, including packaging, construction, automotive, and sports. Its unique properties and benefits have made it a popular choice for manufacturers and designers looking for lightweight, durable, and environmentally friendly solutions.

In the packaging industry, physically cross linked polyethylene foam has revolutionized the way fragile goods are protected during transit. Its exceptional cushioning properties provide a reliable barrier against shocks and impacts, ensuring that delicate items arrive at their destination in perfect condition. Additionally, its lightweight structure allows for cost-effective shipping, reducing transportation costs and environmental impact.

In the construction sector, physically cross linked polyethylene foam has become an essential material for insulation, soundproofing, and moisture barrier applications. Its closed-cell structure provides excellent thermal insulation, reducing energy consumption and enhancing energy efficiency in buildings. Moreover, it acts as an effective sound absorber, creating a quieter and more comfortable living or working environment.

The automotive industry has also embraced the advantages of physically cross linked polyethylene foam. It is widely used for noise reduction and vibration damping, ensuring a quieter and smoother ride for passengers. Furthermore, its lightweight nature makes it an ideal alternative to traditional materials, contributing to improved fuel efficiency and reduced carbon emissions.

When it comes to sports equipment, physically cross linked polyethylene foam offers athletes enhanced safety, comfort, and performance. It is commonly used in protective gear, padding, and shock absorption applications. Its ability to absorb and disperse impact energy helps prevent injuries and allows athletes to perform at their best.

Don’t forget to also review these pages: pe foam, physically cross linked polyethylene foam, chemically cross linked polyethylene foam

Overall, physically cross linked polyethylene foam is a game-changer in various industries. Its applications and benefits are vast, making it a go-to material for packaging, construction, automotive, and sports. With its lightweight structure, exceptional cushioning properties, and eco-friendly nature, it is no wonder that more and more industries are unleashing the power of physically cross linked polyethylene foam.

Packaging Solutions

Discover how physically cross linked polyethylene foam is revolutionizing the packaging industry with its exceptional cushioning properties, lightweight structure, and versatility in protecting fragile goods during transit.

Physically cross linked polyethylene foam, also known as PEX foam, has emerged as a game-changer in the packaging industry. Its unique properties make it an ideal choice for protecting delicate and valuable items during transportation.

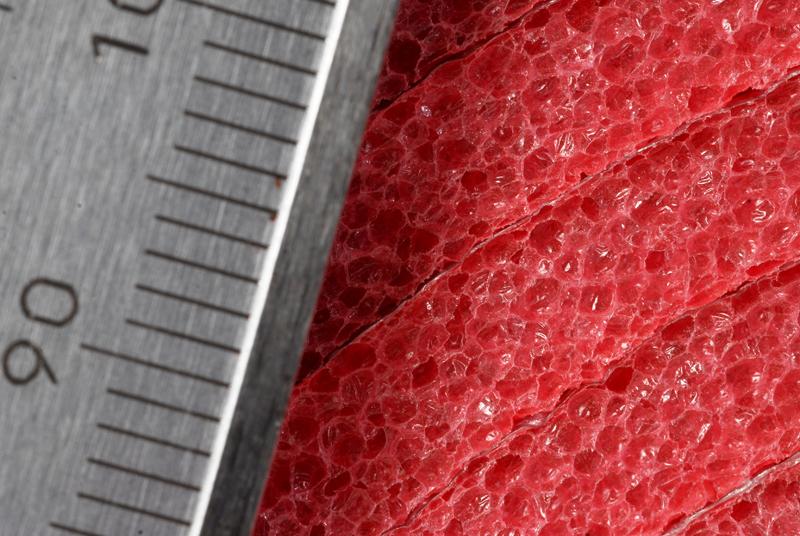

One of the key advantages of PEX foam is its exceptional cushioning properties. The foam’s closed-cell structure allows it to absorb and distribute impact energy, effectively safeguarding fragile goods from damage. Whether it’s electronics, glassware, or delicate machinery, PEX foam provides a reliable protective layer that reduces the risk of breakage.

Furthermore, PEX foam is incredibly lightweight, making it an efficient choice for packaging solutions. Its low density allows for cost-effective transportation, reducing shipping expenses while maintaining the integrity of the packaged items. The lightweight nature of PEX foam also contributes to the overall sustainability of the packaging industry by minimizing fuel consumption and carbon emissions.

Another remarkable feature of physically cross linked polyethylene foam is its versatility. It can be easily customized and fabricated into various shapes and sizes to fit the specific requirements of different products. Whether it’s a small electronic device or a large piece of furniture, PEX foam can be tailored to provide a snug and secure fit, ensuring optimal protection during transit.

In summary, physically cross linked polyethylene foam is transforming the packaging industry with its exceptional cushioning properties, lightweight structure, and versatility. Its ability to absorb impact energy, reduce weight, and provide customized protection makes it an indispensable material for safeguarding fragile goods during transit.

Construction Innovations

Physically cross linked polyethylene foam has emerged as a game-changer in the construction industry, offering a wide range of applications and benefits. One of the key uses of this foam is in insulation, where its excellent thermal properties help in maintaining a comfortable indoor temperature while reducing energy consumption. Whether it’s for residential or commercial buildings, physically cross linked polyethylene foam provides enhanced durability and energy efficiency.

Another area where this foam excels is soundproofing. Its closed-cell structure absorbs and dampens sound waves, making it an ideal choice for reducing noise transmission between rooms or floors. By incorporating physically cross linked polyethylene foam in construction projects, builders and architects can create quieter and more peaceful environments.

In addition to insulation and soundproofing, physically cross linked polyethylene foam serves as a reliable moisture barrier. Its closed-cell structure prevents the ingress of water and moisture, protecting the building materials from damage and ensuring long-term structural integrity. This foam is resistant to mold and mildew growth, making it an excellent choice for areas prone to high humidity.

Overall, physically cross linked polyethylene foam offers construction professionals an innovative material that enhances durability, energy efficiency, and comfort. Its versatility in various applications makes it a valuable asset in the construction industry.

Automotive Advancements

Explore the role of physically cross linked polyethylene foam in the automotive sector, where it is utilized for various advancements. One of the key benefits of this foam is its ability to reduce noise and vibrations. By incorporating physically cross linked polyethylene foam into automotive components, such as door panels, headliners, and floor mats, manufacturers can significantly reduce noise levels inside the vehicle, providing a quieter and more comfortable driving experience.

In addition to noise reduction, this foam also excels in vibration damping. It absorbs and dissipates vibrations, preventing them from transferring to other parts of the vehicle. This not only enhances the overall driving experience by reducing rattling and shaking but also helps to protect sensitive electronic components from damage caused by excessive vibrations.

Another remarkable advantage of physically cross linked polyethylene foam in the automotive industry is its lightweight nature. Compared to traditional materials like rubber and plastics, this foam offers a lightweight alternative without compromising on performance. By using this foam in various automotive applications, manufacturers can achieve significant weight reduction, leading to improved fuel efficiency and reduced carbon emissions. This not only benefits the environment but also helps drivers save on fuel costs.

Substituting Traditional Materials

Physically cross linked polyethylene foam is revolutionizing the automotive industry by replacing conventional materials such as rubber and plastics. This innovative foam offers superior performance, cost-effectiveness, and sustainability, making it an ideal choice for various automotive applications.

- Superior Performance: Physically cross linked polyethylene foam exhibits excellent properties that enhance the overall performance of automotive components. Its high resilience and impact resistance ensure durability and longevity, even in demanding conditions. Additionally, the foam’s ability to absorb vibrations and reduce noise contributes to a smoother and quieter driving experience.

- Cost-Effectiveness: By using physically cross linked polyethylene foam, automotive manufacturers can achieve cost savings without compromising on quality. The foam’s lightweight nature reduces material costs and transportation expenses, while its versatility allows for efficient production and installation.

- Sustainability: One of the key advantages of physically cross linked polyethylene foam is its sustainability. Unlike traditional materials, this foam is recyclable, non-toxic, and produces minimal waste during production. By incorporating this foam into automotive applications, manufacturers contribute to a greener future and reduce their environmental footprint.

Overall, physically cross linked polyethylene foam is transforming the automotive industry by offering a superior alternative to conventional materials. With its exceptional performance, cost-effectiveness, and sustainability, this foam is paving the way for a more efficient and eco-friendly automotive sector.

Enhancing Passenger Safety

When it comes to automotive interiors, safety is of utmost importance. That’s why the utilization of physically cross linked polyethylene foam has become a game-changer in enhancing passenger safety. This innovative foam material is specifically designed to provide exceptional impact absorption, significantly reducing the risk of injuries during collisions.

Physically cross linked polyethylene foam acts as a protective shield, absorbing the force of impact and dispersing it throughout the foam structure. This ensures that the energy from a collision is absorbed, minimizing the potential harm to passengers. By incorporating this foam into various components of automotive interiors, such as seat cushions, headrests, and door panels, manufacturers can create a safer environment for passengers.

Not only does physically cross linked polyethylene foam enhance passenger safety, but it also offers other advantages. Its lightweight nature makes it an ideal choice for automotive applications, as it does not add unnecessary weight to the vehicle. Additionally, this foam is known for its durability and long-lasting performance, ensuring that it can withstand the rigors of everyday use.

In conclusion, physically cross linked polyethylene foam is a crucial component in enhancing passenger safety in automotive interiors. Its ability to absorb impact and reduce the risk of injuries during collisions makes it an invaluable material for manufacturers. By incorporating this foam into their designs, they can provide passengers with a safer and more secure driving experience.

Sports Equipment Advantages

Sports equipment plays a crucial role in ensuring the safety and performance of athletes. Physically cross linked polyethylene foam has emerged as a game-changer in this field, offering numerous advantages in sports equipment design. One of the key benefits is its use in protective gear, such as helmets and padding, where it provides exceptional impact absorption. The foam’s ability to absorb and distribute force helps reduce the risk of injuries during intense physical activities, providing athletes with enhanced safety.

In addition to its protective properties, physically cross linked polyethylene foam also offers superior comfort. The foam’s soft and cushioning nature ensures a comfortable fit for athletes, allowing them to focus on their performance without any distractions. Whether it’s in helmets, knee pads, or other equipment, the foam provides a snug and supportive feel, enhancing the overall experience for athletes.

Furthermore, the shock absorption capabilities of physically cross linked polyethylene foam contribute to improved performance. By absorbing and dissipating impact energy, the foam helps athletes maintain stability and balance, enabling them to push their limits and achieve optimal results. Whether it’s in running shoes, sports mats, or other equipment, the foam’s shock-absorbing properties enhance athletes’ performance by minimizing the impact on their bodies.

The advantages of physically cross linked polyethylene foam in sports equipment are truly remarkable. From offering enhanced safety and comfort to improving performance, this foam has become an invaluable component in the world of sports. With its ability to protect athletes from injuries, provide optimal support, and enhance their overall performance, physically cross linked polyethylene foam continues to revolutionize the sports equipment industry.

Environmental Sustainability

Environmental sustainability is a key consideration in today’s world, and physically cross linked polyethylene foam is making a significant contribution towards this goal. This versatile material is not only highly functional but also eco-friendly, making it a sustainable choice for various industries.

One of the main advantages of physically cross linked polyethylene foam is its recyclability. Unlike other foam materials, this foam can be easily recycled and reused, reducing waste and minimizing the environmental impact. Additionally, the foam is non-toxic, ensuring that it does not release harmful chemicals into the environment.

Furthermore, physically cross linked polyethylene foam produces minimal waste during its production process. This means that the manufacturing process is efficient and does not generate excessive amounts of waste materials. By choosing this foam, industries can contribute to reducing overall waste and promoting a circular economy.

Overall, physically cross linked polyethylene foam is a sustainable choice for industries looking to minimize their environmental footprint. Its recyclability, non-toxic nature, and minimal waste production make it an ideal material for various applications. By incorporating this foam into their products and processes, industries can take a step towards a greener and more sustainable future.

Recycling Initiatives

When it comes to environmentally friendly practices, recycling plays a crucial role in reducing waste and minimizing the impact on our planet. The same holds true for physically cross linked polyethylene foam, which has gained attention for its recyclability and sustainability. In this section, we will explore the efforts and initiatives taken to recycle this innovative foam, contributing to a circular economy and reducing the environmental impact of foam waste.

Recycling physically cross linked polyethylene foam involves a series of steps to ensure its proper disposal and reuse. The foam waste is collected from various sources, such as packaging materials, construction projects, and automotive applications. Once collected, the foam is sorted and processed to remove any impurities or contaminants. This ensures that the recycled foam meets the necessary quality standards for future use.

In recycling facilities, the foam waste is then shredded or granulated into small pieces, making it easier to handle and transport. These smaller foam particles can be used as a raw material for the production of new foam products or other plastic-based materials. This process not only reduces the demand for virgin materials but also helps to conserve valuable resources and energy.

To further promote recycling initiatives, organizations and manufacturers are actively involved in research and development to find new ways to recycle physically cross linked polyethylene foam. They are exploring innovative techniques, such as chemical recycling and foam-to-foam recycling, which aim to improve the efficiency and effectiveness of the recycling process.

By embracing recycling initiatives, we can contribute to a circular economy where resources are used efficiently and waste is minimized. Recycling physically cross linked polyethylene foam not only reduces the environmental impact of foam waste but also supports the sustainable development of various industries, ensuring a greener future for generations to come.

Reducing Carbon Footprint

Discover how the use of physically cross linked polyethylene foam in various applications contributes to reducing carbon emissions and promoting environmental sustainability. This innovative material offers lightweight solutions, minimizing energy consumption and promoting energy efficiency.

Physically cross linked polyethylene foam is known for its exceptional lightweight structure, making it an ideal choice for industries aiming to reduce their carbon footprint. By utilizing this foam in packaging, construction, automotive, and sports equipment, companies can significantly decrease their energy consumption and carbon emissions.

- Lightweight Solutions: The lightweight nature of physically cross linked polyethylene foam reduces the overall weight of products, resulting in lower fuel consumption during transportation. This not only saves energy but also reduces carbon emissions, making it an eco-friendly choice for packaging and transportation industries.

- Minimizing Energy Consumption: With its excellent insulation properties, physically cross linked polyethylene foam helps reduce the need for excessive heating or cooling in buildings. By providing superior thermal insulation, it minimizes energy consumption, leading to lower greenhouse gas emissions and improved energy efficiency.

- Promoting Energy Efficiency: The use of physically cross linked polyethylene foam in automotive applications contributes to enhanced energy efficiency. By replacing heavier materials, this foam reduces the overall weight of vehicles, resulting in improved fuel economy and reduced carbon emissions. Additionally, its vibration damping properties help optimize engine performance, further enhancing energy efficiency.

Overall, the use of physically cross linked polyethylene foam offers a sustainable solution for industries aiming to reduce their carbon footprint. Its lightweight nature, energy-saving properties, and promotion of energy efficiency make it an environmentally friendly choice, contributing to a greener future.